A flexible extension cord may be damaged by a variety of factors, ranging from physical stresses to environmental conditions. Understanding these causes is crucial for ensuring the safe and efficient operation of electrical systems.

Improper handling, overloading, and exposure to extreme temperatures can all contribute to damage, leading to potential hazards and compromised electrical performance.

Identify Factors Causing Damage to Flexible Extension Cords

Flexible extension cords are commonly used to extend the reach of electrical outlets, but they can be easily damaged if not handled properly. Various factors contribute to the deterioration of these cords, including physical stresses, environmental conditions, and improper handling.

Physical Stresses

- Bending and twisting:Repeated bending and twisting of the cord can weaken the internal conductors and insulation.

- Pulling and dragging:Pulling or dragging the cord can put excessive strain on the connections and lead to damage.

Environmental Factors

- Heat:Exposure to high temperatures can melt the insulation and damage the conductors.

- Sunlight:UV radiation from sunlight can degrade the cord’s insulation over time.

- Moisture:Moisture can penetrate the insulation and cause corrosion of the conductors.

Improper Handling

- Overloading:Using the cord to draw more current than it is rated for can overheat the conductors and insulation.

- Improper storage:Coiling the cord tightly or storing it in a damp or dirty environment can contribute to damage.

Analyze Methods to Prevent Damage: A Flexible Extension Cord May Be Damaged By

Preventing damage to flexible extension cords is essential to ensure their safe and reliable operation. Proper handling and storage techniques can significantly extend the lifespan of these cords.

Proper Handling

- Avoid bending or twisting the cord excessively.

- Do not pull or drag the cord.

- Use the cord only for its intended purpose and do not overload it.

Proper Storage

- Store the cord in a dry, cool, and clean location.

- Coil the cord loosely to prevent kinking.

- Use strain relief devices to prevent the cord from being pulled or bent at the connections.

Assess Impact of Damage on Cord Performance

Damage to flexible extension cords can compromise their electrical conductivity and safety. It is important to be aware of the potential consequences of using damaged cords.

Electrical Conductivity

- Damage to the conductors can reduce the flow of electricity, leading to voltage drops and power loss.

- Overheating due to damaged insulation can also reduce conductivity.

Safety Hazards

- Damaged insulation can expose live conductors, increasing the risk of electrical shocks.

- Overheating due to damaged insulation can lead to fires.

Determine Indicators of Cord Damage

It is important to be able to identify signs of damage to flexible extension cords to prevent accidents. Regular inspection and testing can help detect potential issues.

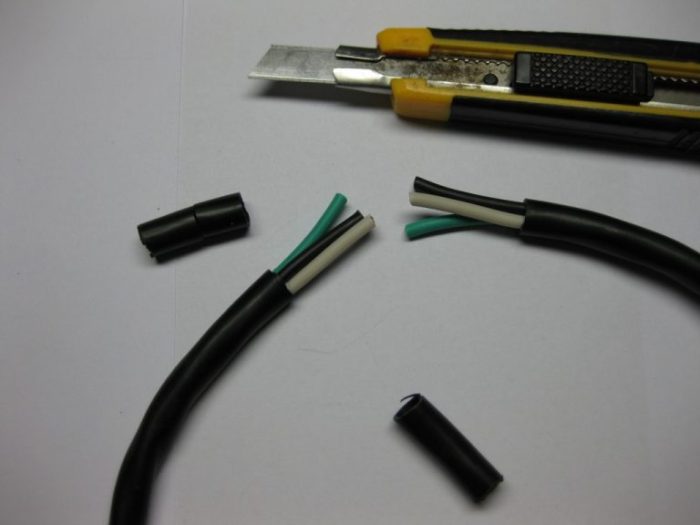

Visual Cues

- Cuts or abrasions in the insulation

- Discoloration or charring of the insulation

- Bulges or kinks in the cord

Electrical Testing, A flexible extension cord may be damaged by

- Continuity test:Checks if the conductors are intact and have no breaks.

- Insulation resistance test:Measures the resistance between the conductors and the ground, indicating the integrity of the insulation.

Hidden Damage

- Internal damage to the conductors or insulation may not be visible from the outside.

- Regular testing and replacement of cords is recommended to ensure safety.

Design Guidelines for Flexible Extension Cords

Industry standards and best practices guide the design of flexible extension cords to ensure their durability and safety. These guidelines address materials, construction, and performance.

Materials and Construction

- Conductors:Copper or aluminum conductors are used for their conductivity and flexibility.

- Insulation:Rubber, PVC, or other insulating materials protect the conductors from damage.

- Sheath:A protective outer layer made of rubber, PVC, or other materials provides additional durability.

Performance Requirements

- Electrical ratings:Cords are rated for specific voltage and current capacities.

- Temperature ratings:Cords are designed to withstand a range of temperatures without damage.

- Durability:Cords must be able to withstand bending, twisting, and other physical stresses.

FAQ Compilation

What are the common causes of damage to flexible extension cords?

Physical stresses such as bending, twisting, and pulling, as well as environmental factors like heat, sunlight, and moisture, can cause damage to extension cords.

How can I prevent damage to my flexible extension cord?

Proper handling and storage techniques, avoiding bending and kinking, and using strain relief devices can help prevent damage to extension cords.

What are the potential consequences of using a damaged extension cord?

Damaged extension cords can affect electrical conductivity and safety, posing potential fire hazards and electrical shock risks.